Livestock Manure Sampling and Analysis

As you develop crop nutrition plans for the upcoming year, it is important to include spring manure application in the crop nutrition budget. Manure is an excellent source of plant-available nutrients and offers nice economic savings, especially with high fertilizer prices. When manure is applied properly, you can maximize the nutrient value, reduce nutrient losses, and comply with government regulations.

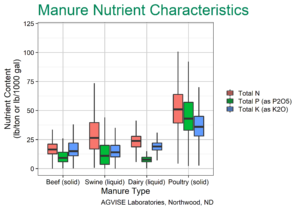

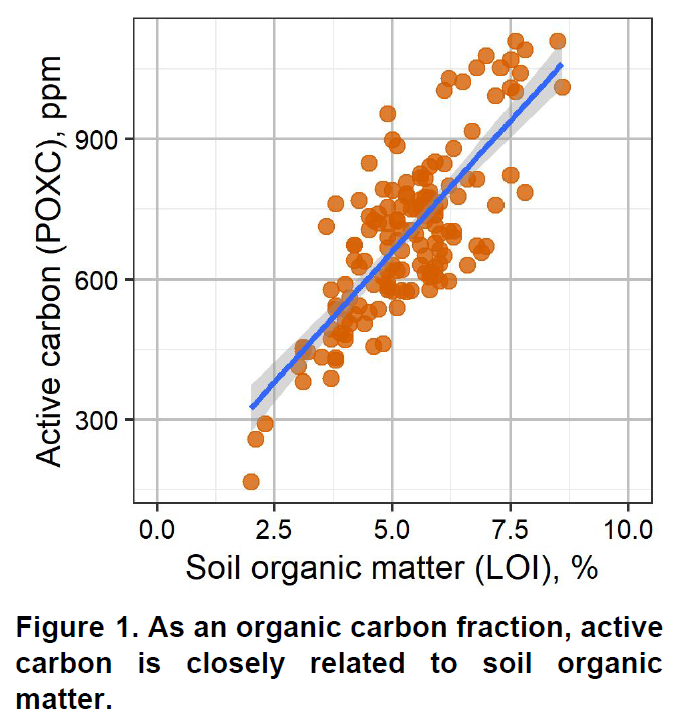

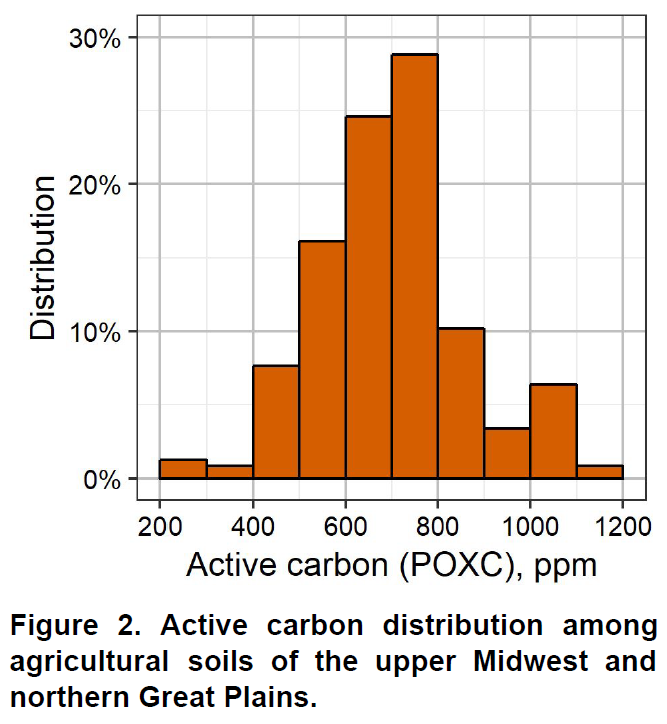

A proper manure nutrient management plan starts with soil and manure analysis. AGVISE Laboratories provides both soil and manure analysis as routine services to help you develop the right manure nutrient management plan. You might find “book values” with average manure nutrient contents for different manure types, but there is a lot of variability among manure sources from farm to farm. Would you purchase commercial fertilizer without knowing the nutrient analysis? I do not think so! The manure nutrient concentrations vary widely because of dry matter/moisture content, livestock species and age, bedding type, and feed rations. Each year, AGVISE analyzes thousands of manure samples, and the nutrient content range can be very large (Figure 1). A manure analysis is a quick way to know the dollar value in your manure.

Figure 1. Manure nutrient characteristics of manure samples sent to AGVISE Laboratories, 2013-2020. For any nutrient and manure type, there is substantial variability from manure source to source. The box-and-whisker plot represents the median (middle) nutrient content at the thick middle bar, the 50th-percentile range within the box, and the minimum and maximum variability with the whiskers.

A good manure analysis starts with a good manure sample. Here are a few tips and tricks in collecting a representative manure sample. AGVISE provides manure sample containers at no cost, so please contact us if you need manure sampling supplies.

Solid Manure

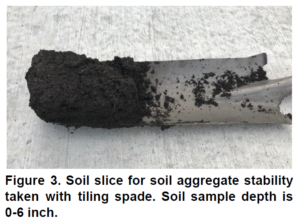

Collect several small manure samples using a shovel or pitchfork in the manure pile or bedding area, place in a clean plastic bucket. Avoid the top or edges of the pile where a crust has formed. Mix the bulk sample well, then submit one subsample for analysis in plastic jar (about 1 pint). Store in refrigerator or freezer until shipped. Place in tightly sealed plastic bag to prevent leakage in shipment. Multiple samples may be necessary if the storage area includes manure for different lengths of time.

Liquid Manure

Before sampling, the liquid storage system must be agitated to mix liquid and solids. Collect several samples in a clean plastic bucket. Mix the bulk sample well, then submit one subsample for analysis in a plastic jar (about 1 pint). Store in refrigerator or freezer until shipped. Place in tightly sealed plastic bag to prevent leakage in shipment.

Once the manure analysis results are back, you can begin creating a manure nutrient management plant with the soil and manure test results. The soil test results will determine the crop nutrient requirements to maximize crop yield and profitability. Then, subtract the amount of crop nutrients provided in manure, and apply any remaining crop nutrient requirements with commercial fertilizer. A good manure nutrient management plan will help you maximize economic return on manure inputs. In addition, check with local and regional government agencies for any special requirements in your area.

In recent decades, regulation and public concerns have changed the way we handle manure nutrient management. It is a valuable nutrient resource, which when managed properly, can increase profitability, improve soil properties, and protect the environment.

For additional information on manure analysis and land application, these are some helpful online publications. If you have any questions on manure analysis, please contact the AGVISE technical support team.

Manure Sampling and Nutrient Analysis (University of Minnesota)

Step-by-step Manure Rate Calculations (University of Minnesota)

Manure Application Methods and Nitrogen Losses (University of Minnesota)

Manure Management Guidelines and Fact Sheets (Manitoba Agriculture)