Soil sampling in dry conditions can be difficult. The ground is hard, fields are dry, and getting a consistent soil core depth can take more time than usual. To help you take the best soil samples this fall, we’ve put together some tips and tricks for sampling in dry soil conditions that, when implemented, will help you save time and frustration in the field.

Soil sampling equipment

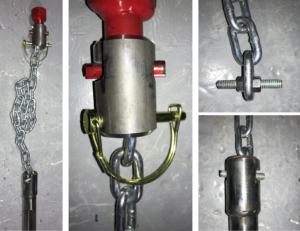

AGVISE Laboratories has provided soil sampling equipment for over 40 years. Our hydraulic soil sampling system will enable you to get high-quality soil cores, even in hard, dry soils. The electric-hydraulic power unit paired with easy-to-change Quicktach probes will make adapting to challenging soil sampling conditions simple and easy. You can find more about our equipment on our online store.

Best soil probe body

The heavy-duty (HD) probe body is made from chromoly steel. This thick-walled, hard steel probe body will resist bending under hard, dry, or frozen soil conditions (compared to softer stainless steel). The HD probe body comes in two options: solid and slotted. If the topsoil is powder dry, it is best to use the HD solid probe body, as powder-dry soil may fall out of the slot. Stainless steel probe bodies work great in most situations but in hard, dry soils the stainless-steel probe body may bend more easily than the HD probe body.

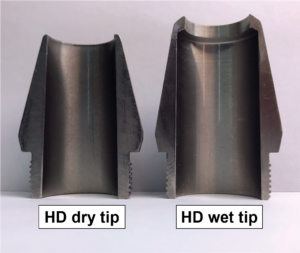

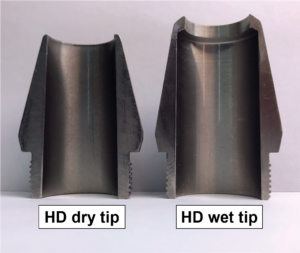

Best soil probe tip

AGVISE Laboratories carries two tips for the HD probe body. The HD “dry tip” has a sharp cutting edge and large opening (3/4-inch) that works great in hard, dry soils. It is our leading recommendation for such conditions. If you are soil sampling fine-textured clay soils, even under dry conditions, the HD “wet tip” may also work well for you because there is usually a little moisture remaining at the lower end of the 24” soil profile. It is a good idea to have both the HD dry and HD wet tips with you in the sampling rig. As soil conditions change, you can use the soil probe tip that gives you the best quality soil cores.

Solving common very dry soil sampling problems

What do I do if the soil probe comes up empty?

Under very dry soil conditions, sometimes the soil probe comes up empty because soil falls out the bottom of the probe. One trick to overcome this is to push the probe all the way to 24-inch (or to the end of its cycle), then lift the probe up a few inches and push it back down to 24-inch. This creates a slight plug at the bottom of the soil core that prevents soil from falling out the bottom. It seems like such a simple solution, but it works!

What if I can’t get full 24-inch soil cores and the soil probe tip has a hard plug in it, which is preventing soil from flowing into the probe body?

You are probably using a tip with an opening diameter that is too small. Dry soil does not compress well and sometimes it will not flow through a smaller tip opening. The HD dry tip has a 3/4-inch that is large enough to allow dry soil to flow into the soil probe.

Will WD-40 help me get better quality soil cores if the soil is dry and hard?

There is no benefit to using a lubricant such as WD-40 under very dry soil conditions. Dry soil is much less likely to plug the soil probe than wet soil. If you are running into a few plugged tips with the HD dry tip, try the HD wet tip. You are probably finding a layer of wet soil deeper in the soil profile. The HD wet tip has a recessed lip that will prevent plugging and will handle this layer better than the HD dry tip.

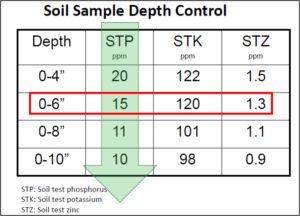

What if I can’t get a full 6-24-inch soil core? Should I change anything in the information I submit to the laboratory?

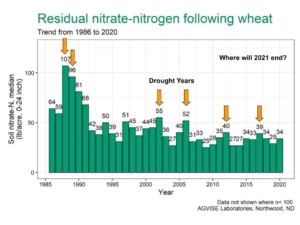

If you are unable to get a full second soil depth (6-24-inch soil core), it is important that the information you submit to the laboratory matches the soil depth you actually collected. Mobile soil nutrients like nitrate-nitrogen are tested on the second soil depth and results are calculated based on soil core length. If the soil core is shorter than what was written on the submission form or submitted in AGVISOR, the soil test nitrate-nitrogen result will be overestimated.

Preventing fires when soil sampling

No one wants to start a fire while in the field. Unfortunately, driving anything with an engine over dry crop residue creates a fire risk. John Lee, soil sampling and testing veteran, has seen this happen firsthand. “I started a corn stalk field on fire when I was soil sampling one of my dad’s fields in college,” said Lee. “The fire was put out quickly, but I was embarrassed that I did not have anything in the truck with me to put the fire out.”

After visiting with several customers with many years’ experience soil sampling in dry conditions, we compiled a list of practices that can reduce the chance of fire while soil sampling.

Fire suppressing items to keep in your soil sampling rig

Remember that most fires start under the truck where straw or chaff accumulates on exhaust pipes, mufflers, etc. Your firefighting equipment needs to be long enough to reach these areas if a fire does start.

- Large ABC type fire extinguisher with hose

- 10 lb size costs ~$70.00; large 20 lb size costs ~$130.00

- Water tank with 20-ft hose

- A small water tank (~25 gallons) with a 20-ft hose will allow you to get to any location on the truck to put out a fire. One sampler suggested using a small spray tank system designed for ATVs. The systems cost roughly $350-$450, are self-contained, and run from a battery. You may already have a small weed spraying system you can put in the box of your soil sampling truck to use as a firefighting system.

Practices to reduce fire risk before one starts

- Soil sample in the morning when it is cool and overnight dew is still present

- Talk with your clients about reducing stubble height. This should not be an issue with drought-stressed crops because the stubble height will be shorter than normal.

- Keep as much ground clearance under your truck as possible to prevent chaff buildup on the frame, axels, and crossmembers.

- Inspect your truck at the end of each day to make sure straw and chaff are not accumulating in places that could start a fire the next day. Use an air compressor to blow out all the nooks and crannies accumulating crop residue.

- Stay alert for any hints of smoke while soil sampling. At the first hint of smoke, find where the smoke is originating quickly and extinguish it, or get out of the field and into a safe area to figure out where the smoke is coming from.